Efficient, safe and durable insulation solutions

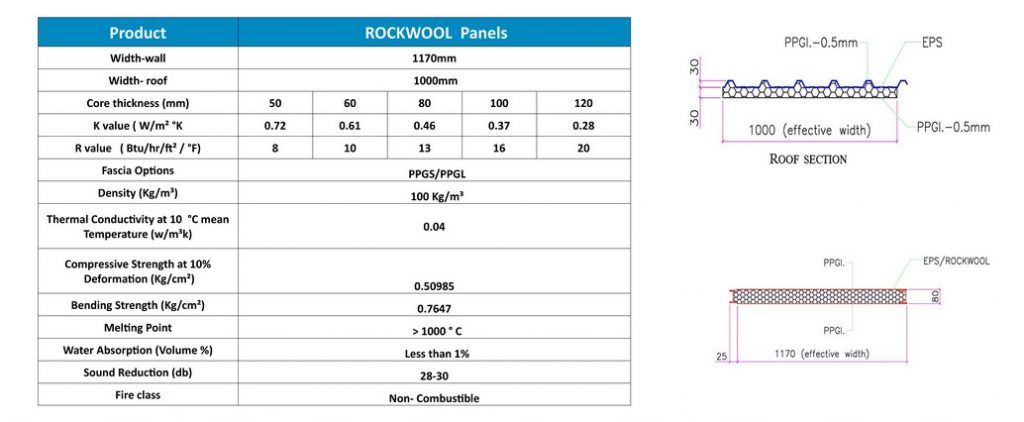

Rockwool insulation panels offer protection from cold, heat, risk of fire and ambient noise. LA Rockwool panels comprise of pre-fabricated composite sandwich panels with high density Rockwool insulation as core and profiled or plain color coated galvanized steel or galvalume steel sheet on either side.

These Rockwool acoustic wall panels provide a pleasant indoor experience while reducing energy costs.

Best-in-class rockwool panel features

- Rockwool cores provide non-combustibility and outstanding acoustic performance.

- Rock wool sandwich panels can be installed horizontally and vertically.

- Easy to install and handle.

- Easy assembly with simple lifting equipment without the need of scaffolding.

- Free from thermal bridging as a benefit of high thermal insulation.

- Wide range of surface design and color finishes for walls and roofs.

Rockwool sandwich panel manufacturing technology

LA Rockwool Panels are manufactured on the most modern continuous panel manufacturing technology and can be supplied in lengths up to 12m (limited due to restriction in transportation). Rockwool panels have very high sound proofing properties and are fire resistant. With an expertise in manufacturing the best Rockwool acoustic panels, LA offers a one step solution for sound proof room in the form of acoustic wall and ceiling sound absorbing panels.

A unique solution for multiple applications

LA offers the right acoustic foam panels to suffice varying construction, industrial and commercial application. Incorporating innovative technology, we offer a complete range of modern and reliable insulation materials for the following applications:

- Control rooms

- Turbine-Generator Buildings

- Power project buildings

- Drivers and ovens insulation

- Compressor rooms

- Acoustic rooms

- HVAC ducting

- Fire safety applications